Sept-Dec 2025: Thin Film Sensor Manufacturing Research @ Uwaterloo CAMJ

At CAMJ under Prof. Peng, I prototyped thin-film strain sensors for ForceN by UV laser-cutting NiCr traces, then validated resistance and cut quality under a microscope. This section shows the process improvements, failure analysis, and the indexing platform I built to expand the cutting envelope for larger designs.

These are full wheatstone bridge strain guages - note the visible production quality difference of old versions vs mine

I dialed in power / speed / pulse rate to hit 1000 Ω ±10 Ω (down from ±90 Ω). Other manufacturing improvements include:

rolling infill epoxy on with pipette vs smearing

pre-soldering contact pads

respaced traces to reduce HAZ- induced failures

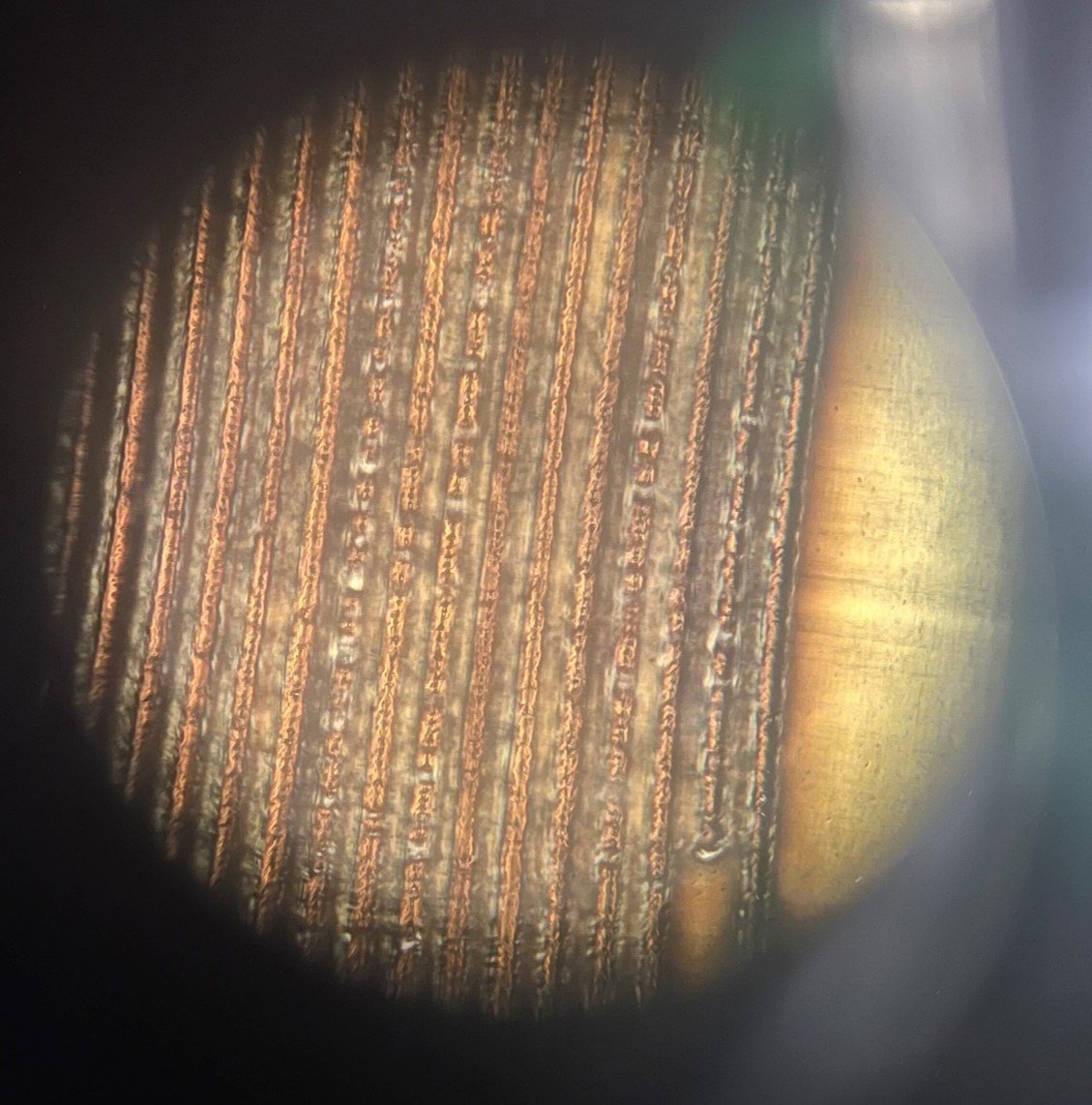

This is a 20x zoom on the strain guage resistor traces - revealing the laser can melt/reweld material, leaving those tiny “bridges” you see between the lines

This shorts the circuit and drops resistance below spec.

I found that low resistance isn’t just “too little power = not cutting the NiCr” it’s driven by the combination of pulse rate + power (certain settings behave like a bad frequency window).

Used this insight to avoid the short circuits and get clean, repeatable cuts.

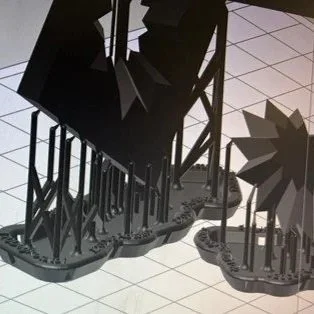

The UV laser only cuts effectively inside an area ~25 mm in diameter. We needed to cut much larger samples, so I found a solution; rotate the work under the beam and stitch multiple cuts together like pieces of a pie. (New effective diameter = 52mm)

I SLA-printed 30° indexed male/female “star” wedges (show on the left image) for repeatable positioning + wrote an SOP on how to calibrate the stage & software. (the right image shows steps of calibration)

Result: only ~5 µm of runout across 12 index steps (measured at ~20 mm radius) — stable enough to stitch larger patterns reliably. (stitch alignment is shown in bottom left of right image)

Jan-April 2025: Fire Safety Engineering @ SENEZCO

I worked for SenezCo, a fire science & engineering firm focused on performance-based design, code consulting, and forensic analysis. I contributed to site investigations, FDS smoke modelling, and BCFC/NFCC compliance reporting to support safe, reviewable design decisions.

FIRE

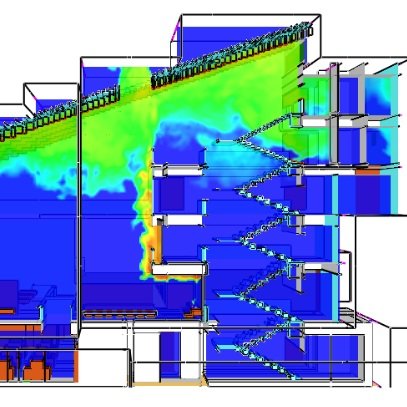

This is a smoke movement simulation built in FDS

I modeled smoke paths and accumulation - used outputs to recommend fire safety measures (e.g., compartmentation/venting strategies) aligned with BCFC / NFCC requirements.

This is a figure from a code compliance report (BCFC / NFCC)

I wrote client-facing compliance reports that turn code into clear, defensible design decisions.

These tedious reports taught me how to write rigorous documentation: structured reasoning + diagrams/figures + code.

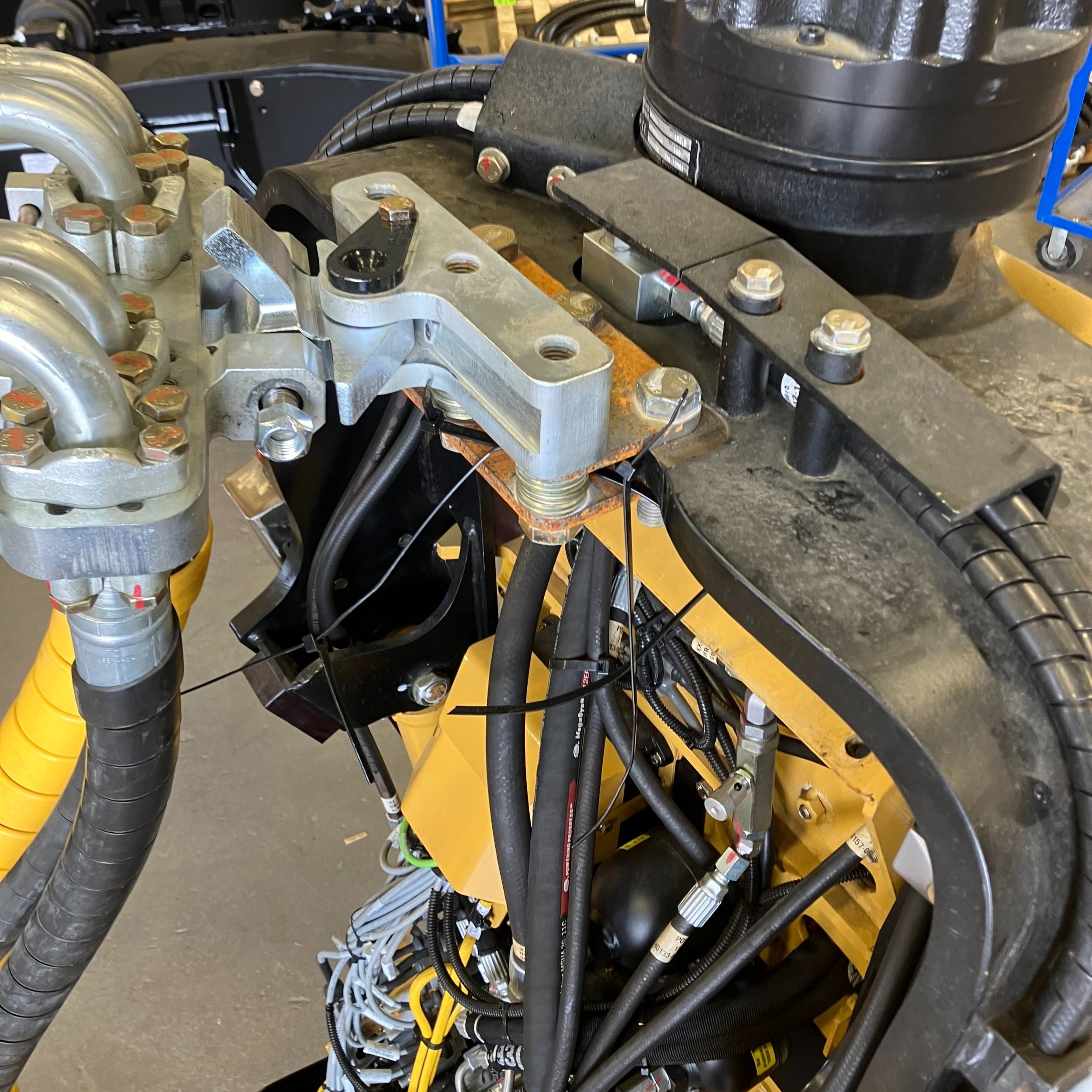

This is a manifold from a sprinkler failure investigation. To diagnose the burst head,

I documented the entire system + its conditions to support corrective action + code follow-up.

May-Aug 2024: 1165 Harvester Product Design @ TIGERCAT

At Tigercat, I supported product design work on the 1165 wheel harvester—a machine built for steep-terrain forestry with features like a leveling cab/crane and a dedicated hydraulic system for drive/head/crane functions.

I learned how to ship changes inside a large, multi-site manufacturing organization

This is the 1165 harvester

One project was designing a wiring harness for new leveling sensors: that meant finding new routing paths, new mounting hardware, connector selection, testing, and through to updating manufacturing drawings.

Another project was reverse-engineering a competitor’s joystick control pods so an operator switching brands could keep familiar control feel.

Problem: Hydraulic cables are strained by rotation of cutting head.

My solution:

machining and iterating this swivel gallery + swivel head to control hose/cable routing near the head (this greatly reduced snag/chafe risk and improving reliability).

I prototyped quickly, tested fit/function, then refined toward a manufacturable solution.

These are Fire extinguisher mounting brackets

I designed the whole production; packaging, laser-cutting, site to site delivery, forming, tapping & welding.

This simple bracket taught me large-company execution: revision control, clear drawings/BOM discipline, and cross-site communication to get these built correctly the first time.

Sept-Dec 2023: Gear & Powertrain Manufacturing @ ON.DRIVE & GEAR

I worked for Ontario Drive & Gear, a manufacturer known for designing, manufacturing, and assembling gears/gearbox and transmission assemblies. I learned to worked in a production-minded environment where documentation and repeatability matter.

Before I designed and sourced protective these plastic separators the gears were separated by loose dunnage!

I Improved part protection and made staging/transport cleaner and more consistent for the new cleaning workflow I put together

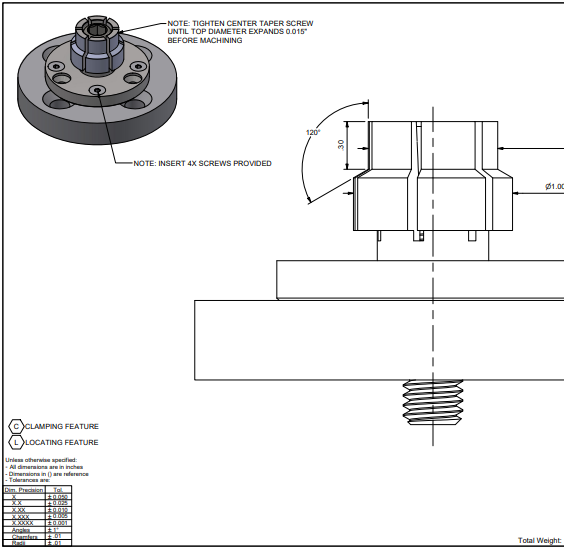

This is the front page to an assembly/drawing package I created for the tooling machinist. I implemented multiple locating features so multiple gear types can be cleaned on the same system.

This was designed with repeatable loading, stability during brushing/air-jet cleaning, and fast changeover in mind.

This was an old deburring machine I repurposed to clean a variety of gears.

In the photo you can see a horsehair wheel brush + angled air jet matched to the helical angle, controlled with PLC I implemented.

For the brush arm to insert to the right spot for any gear diameter/height I had to implement a sensitive pressure sensor whereas the air jet simply ran on a timed cycle.

Result: cycle time went from 5 min by hand to 30 sec per part, with reduced nicking/handling damage. (These parts were particularly sensitive to damage because they had to be cleaned after they are cut but before they are case hardened.)

Jan-April 2023: Vibration Analysis & NDT @ BTA RELIABILITY

At BTA Reliability Centered Maintenance, I did predictive maintenance work (NDT, oil analysis, vibration analysis) at heavy industrial sites like Highland Valley Copper—where unplanned downtime is brutally expensive, so the goal is to find failure early and schedule work during planned downtime.

These pumps aren’t moving clean water—they’re moving abrasive copper ore slurry, so wear is expected and failures must be predicted

As well as the conveyor belts - I did condition checks to estimate remaining life so pumps could be replaced during scheduled downtime—not during production.

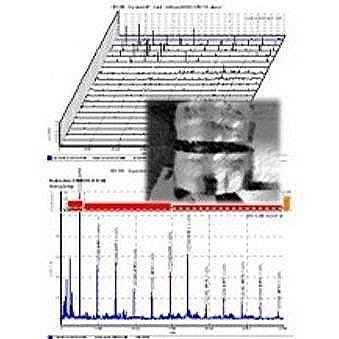

The vibration data I collected in the field (right image) was analyzed with trends/spectra in SKF Observer (it roughly looks like the left image) spikes at certain frequencies indicate certain types of failures.

This is a conveyor belt at the largest copper mine in Canada: Highland Valley Copper. I remember there being ~50 drive/lag/tension bearings for just the conveyors I would inspect and provide maintenance reports for.

I was also contracted to write a safety audit concerned with how contractors like BTA collect data from running machinery - designing guardrails and such. HVC paid BTA $50000 for this audit.

SUMMER 2022: Construction Labour @ SPOONER INDUSTRIAL

These are 4 transducer samples I made from scratch myself; designing, cutting, applying cover film, soldering, mounting, and eventually delivering in person to the company funding the research - ForceN

These are 4 transducer samples I made from scratch myself; designing, cutting, applying cover film, soldering, mounting, and eventually delivering in person to the company funding the research - ForceN

SUMMER 2021: Bicycle Manufacturing @ WAO COMPOSITES

These are 4 transducer samples I made from scratch myself; designing, cutting, applying cover film, soldering, mounting, and eventually delivering in person to the company funding the research - ForceN

These are 4 transducer samples I made from scratch myself; designing, cutting, applying cover film, soldering, mounting, and eventually delivering in person to the company funding the research - ForceN

These are 4 transducer samples I made from scratch myself; designing, cutting, applying cover film, soldering, mounting, and eventually delivering in person to the company funding the research - ForceN